Industrial effluents treatment, treatment systems of household solid waste filtrate.

NTT is a manufacturer of integrated treatment facilities for household solid waste filtrate. The developed technology has a wide versatility, high technological efficiency and stability of the purification process over time

NTT is a manufacturer of integrated treatment facilities for household solid waste filtrate. The developed technology has a wide versatility, high technological efficiency and stability of the purification process over time.

Landfills of solid household (municipal) waste produce filtrate water (hereinafter referred to as filtrate) in a result of atmospheric precipitates infiltration (seepage) through the disposal basins, emission of squeezed water and biochemical processes of municipal waste degradation under the influence of weather factors and depositing conditions.Peculiarities of filtrate waters of landfills are:

-

complex chemical composition, represented by organic and inorganic contaminants;

-

change in the contaminants' composition at each stage of the landfill life cycle;

-

high content of toxic components, hard-to-degrade impurities and heavy metals;

-

presence of different groups of microorganisms in the water, including pathogens;

-

a significant difference from the municipal sewage;

-

dependence of the volume and composition of filtrate water on the landfill size, volume of disposed waste and the amount of atmospheric precipitation.

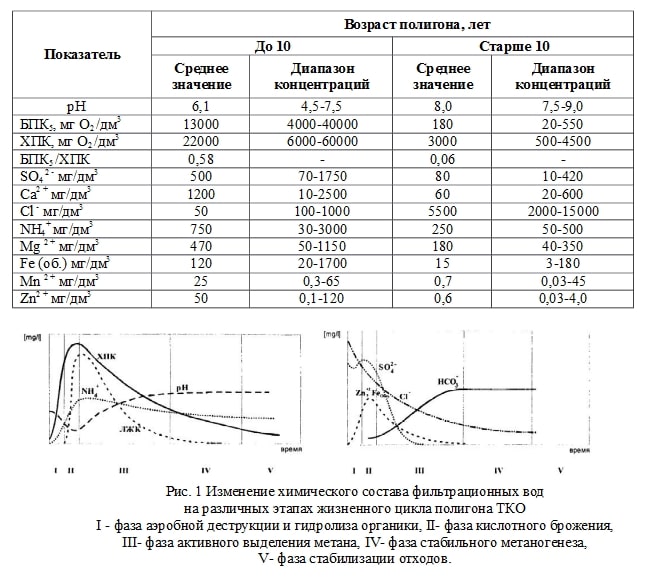

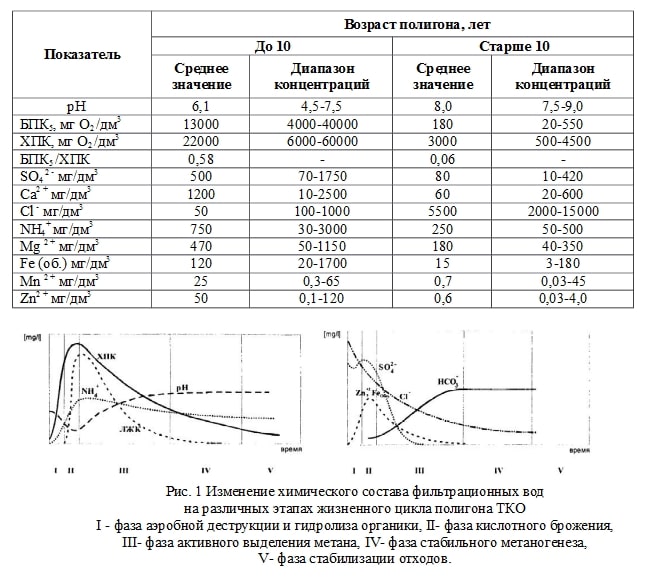

Chemical composition of a typical landfill filtrate water depending on the stage of the life cycle is characterized by the indicators presented in Table 1, which are dozens of times higher than in household sewage. Changes in the chemical composition of municipal solid waste filtrate by years can be represented by the scheme shown in Fig. 1.

The above features of solid household waste filtrate must be taken into account when developing the technology of their treatment. For sewage treatment facilities it is necessary to use integrated technologies that combine mechanical, biological and physical-chemical methods of treatment.

The choice of technologies and facilities for filtrate water treatment is made in accordance with the following principles:

-

application of highly efficient technical solutions and technologies appropriate to the landfill life-cycle stage, technical and economic feasibility and adequate to the climatic conditions of the landfill location;

-

flexibility in controlling the treatment process when the effluents composition changes in the result of seasonal fluctuations and the landfill lifecycle stage;

-

use of simple in operation and proven technologies;

- use of durable materials in treatment technology.

-

landfills under construction;

-

landfills in active operation;

-

landfills in the process of shutdown, rehabilitation

-

landfills with a life cycle of more than 30 years.

For the landfills being designed, assessment of changes in the concentration of organic substances in the filtrate is carried out by methods of forecasting the filtrate composition, taking into account the morphological composition of the solid municipal waste and the rate of surface precipitation.

The choice of filtrate treatment technological procedure in accordance with the sanitary requirements for the quality of treated water is implemented by taking into account the actual stage of the landfill life cycle and the best appropriate treatment methods.

As the " Processing and Waste Disposal Plant in Solnechnogorsk Municipal District (Solnechnogorsk Urban District), Moscow Region" is a newly built landfill for solid municipal wastes, its filtrate will be characterized by high organic pollution content (BOD5 / COD - 0,8-0,6) optimal for biological treatment.

For new designed landfills the most promising are block-modular technological systems of filtrate treatment, allowing to manage the process when changing according to the life cycle stages.

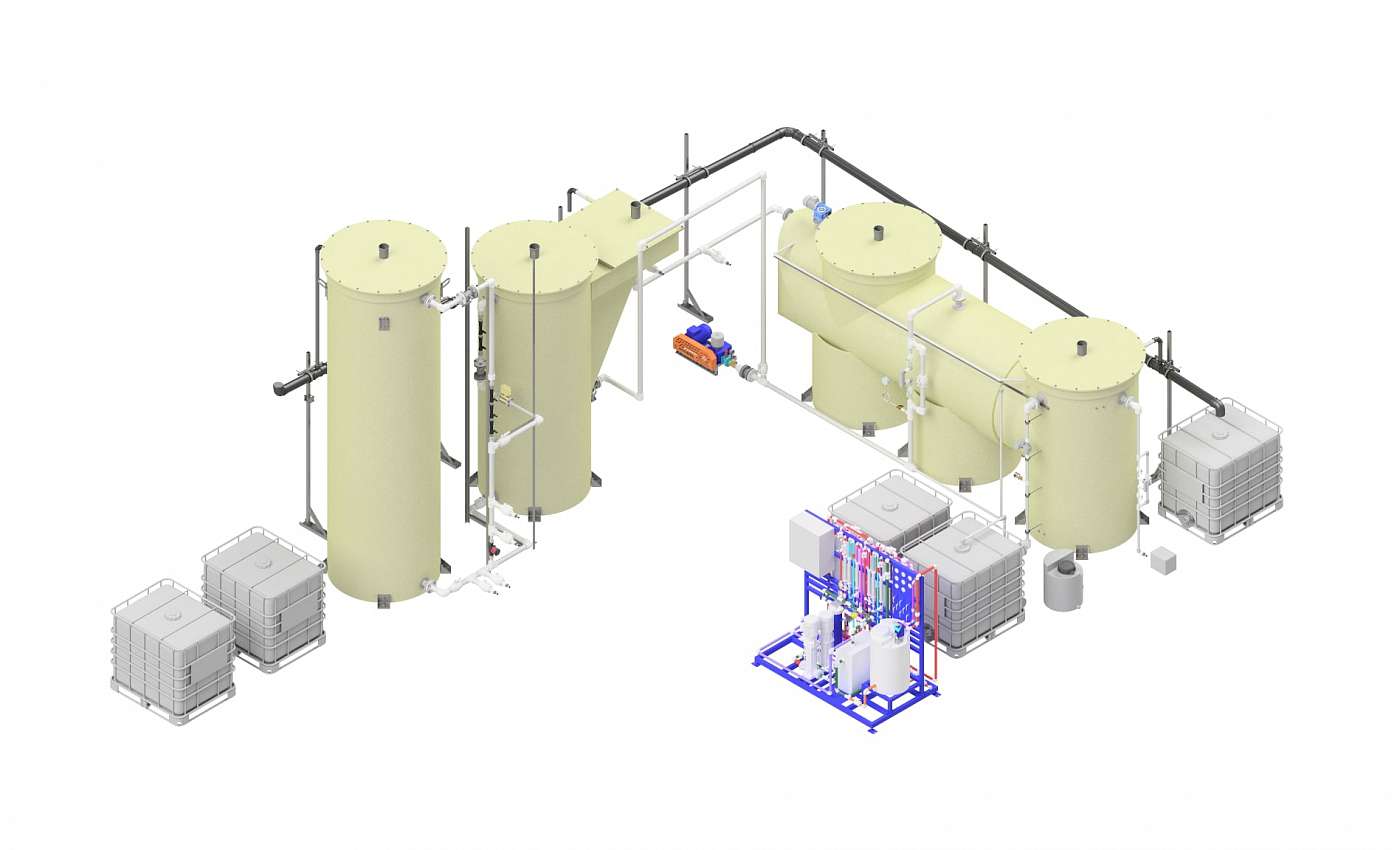

Treatment facilities for solid municipal waste filtrate for disposal sites manufactured by NTT consist of the underground tank equipment and above-ground containers of complete factory design in accordance with TU 28.29.12-006-99675234-2019.

All underground facilities are made from unified construction blocks of GRP pipes 1800-3000 mm diameter with ring stiffness 5000 to 10000 Pa produced by the plant according to TU 22.21.21-004-99675234-19, TU 4859-005-81652345-2015. The use of GRP as a construction material provides corrosion resistance of tank equipment against reagents, high mechanical strength and a long service life of sewage treatment facilities.

In above-ground containers there are reverse osmosis units, blowing station, air filter and mechanical dewatering unit of the generated sediments.

Justification of the technological design of NTT treatment facilities is made according to the BAT Guide ITS 8-2015 (list of information and technical reference books on the best available technologies).

.jpg)

One of the main procedures of preliminary mechanical treatment is treatment with reagents (coagulants, flocculants, etc.) in a tank of sufficient volume ensuring the possibility of removing the sediment, which can be generated up to 2 tons of dry substance daily at the treatment facilities of this Processing and Waste Disposal Plant. The method of reagent sedimentation is used in combination with filtration and sedimentation at high concentrations of heavy metals in effluents.

At effluent filtrate treatment plants, the first stage is reagent precipitation of heavy metals with a purification efficiency of 99.3 - 99.7%. The second stage of heavy metals removal is connected with their binding by active sludge in a membrane bioreactor (MBR). The final post-treatment is carried out at the reverse osmosis unit with high selectivity of membranes ≈ 98%. Thus, the overall efficiency of the two-stage treatment provides a purification efficiency from heavy metals of more than 99.99%.

Membrane bioreactor technology (hereinafter referred to as MBR) of landfill filtrate treatment facilities has been used for more than 25 years all over the world. MBR technology is the most stable and reliable method of treating newly produced filtrate with a high content of organic pollutants. It is very often even used as the only stage of landfill effluent treatment in Germany.

The use of MBR finely dispersed aeration reduces power consumption for oxidation of organic pollutants by several times compared to ozonation.Reverse osmosis unit makes it possible to guarantee removal of even high concentrations of heavy metals in case of huge inflow of contaminants and reuse the treated water for technological needs.

NTT offers an innovative technology for solid waste filtrate treatment, tested on wastewater samples from a similar waste processing plant.The technological process includes 3 consecutive stages of treatment (mechanical, biological and membrane purification). Each stage performs a clearly defined function and provides reliable filtrate treatment.

This technology is comprehensive and flexible, easily adapted to changes in the composition and volume of contaminants and allows the full use of treated water for technical needs.

.jpg)

Such technological plan of NTT treatment facilities for filtrate effluent treatment of Processing and Waste Disposal Plant in Solnechnogorsky Municipal District meets the regulations of the BAT reference book ITS 8-2015 " Effluent treatment in products (goods) production, carrying out works and rendering services at large enterprises"..

Video about the unique complex biomembrane technology for treatment of solid waste filtrate