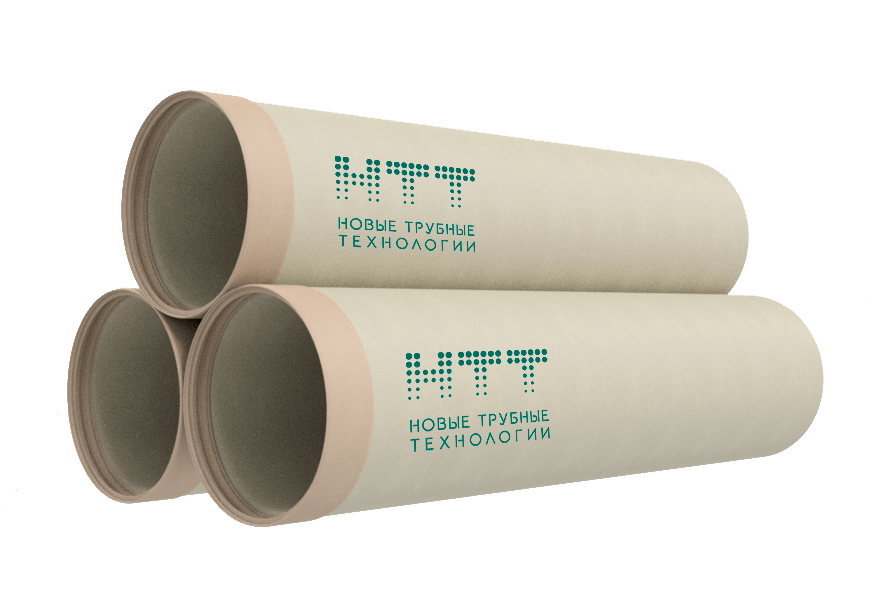

Fiberglass pipes NTT CHEM

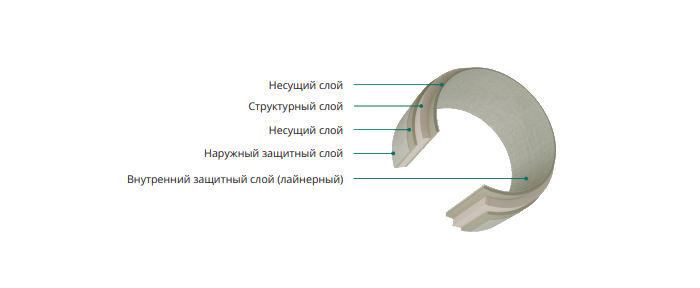

A unique innovative product based on special chemically resistant binder, its resistance to aggressive environments surpasses such materials as reinforced concrete and steel, and its economic efficiency exceeds polyethylene, cast iron and polypropylene

Helpful information

Helpful informationMany years of using pipes made of traditional materials (steel, cast iron, polyethylene, etc.) for household sewage systems have shown the need to develop a modern material for pipe production, surpassing the characteristics of existing analogs. Fiberglass plastic, which has high chemical resistance, excellent hydraulic characteristics and resistance to chemical and gas corrosion, has become such material.

NTT CHEM pipe is used for systems of industrial and municipal household sewage, rainwater sewerage, transportation of chemically aggressive and abrasive media, technical pipelines of industrial plants, rehabilitation of existing pipelines, restoration of pipelines by relining, pipelines of output sewage collectors in the sea and other pipelines designed for water removal.

Pipes for industrial sewage.

Industrial sewage is quite different from household sewage. During the operation the enterprise releases contaminated liquid, for its treatment a proper installation of sewage system is required. The industrial sewage system includes the following components: pumping stations, sewage networks, purifying filtering devices, sewage collectors, etc. The quality of production depends on the correct organization of sewage utilities at the enterprise. Therefore, the industrial sewage system must meet all the necessary requirements.

Pipes for municipal household sewerage.

Municipal sewerage is an industry that enables the optimal functioning of various structures and residential buildings, and is one of the important elements of life support of cities and various settlements. Municipal sewerage belongs to the centralized system of taking wastewater from the inhabitants and its further treatment, where sewerage pipelines serve for household waste output. There is also a high demand for sewage pumping stations (SPS), sewage treatment facilities (STF), storage tanks and wells in the system of municipal sewerage. No surface runoff and drainage water are allowed to be received from the territories of cities and industrial sites into the sewage system.

Pipes for rainwater sewerage.

Rainwater sewerage is a system that protects the foundations of buildings and the areas that surround them from rain and melt water. Its main task is to collect rainwater and meltwater in a series of canals. In general, the system is able to stop foundation flooding, which can lead to the destruction. Rainwater sewerage is a must-have in construction engineering. A professionally designed rainwater sewerage system, aligned with all factors, ensures constant and quality discharge, thus keeping foundations from collapsing.

Pipes for transportation chemically aggressive and abrasive media.

Pipelines are used by large industrial enterprises for transporting aggressive and abrasive media. A distinctive feature of pipes is the ability to withstand the impact of aggressive outer environment and negative temperatures. In the production process of pipes which are resistant to chemically aggressive media, we use unique resin, additional pipe insulation and special outer coating. It is one of NTT LLC achievements.

Pipes for rehabilitation/relining of existing pipelines.

In dense city developments and existing traffic highways, conventional trenching of pipelines proves to be unsuitable or excessively costly. After rehabilitation/relining process, the working diameter is reduced, but GRP pipes make it possible due to the excellent hydraulic characteristics. The process is carried out by pulling (pushing) method, when a new pipe is installed inside the defective one, or by moving sections of GRP pipes inside the pipeline by an electromechanical platform.

Pipes for output sewage collectors.

Collectors are divided into: a) sewage collectors collecting effluents from the sewage network of one basin; b) main collectors collecting effluents from two or more collectors of sewage basins; c) out-of-town (or output) collectors removing effluents by transit (without connections) outside the sewage site to pumping stations, treatment facilities or to the discharge point into a water basin.

NTT CHEM pipes are modern, high quality and available products, which are in many ways better than their analogues. Their application range is very diverse and is constantly expanding.

Fiberglass pipes, as opposed to steel, cast iron, polyethylene pipes, are easy and convenient to install. For the installation of pipes there is no need for complicated connections, such as: welding, socket connection, additional seals, hermetic. With GRP pipes, their connection is made by socket, which is already on the pipe. In order to make it possible to lay pipes on the ground, special UV protection and additional insulation against negative temperatures are used in the pipe production process. In above-ground pipe laying, it is important to comply with the operating conditions.

Proper maintenance should be done to prevent significant deterioration of the performance and operating quality of the pipeline. Proper maintenance is necessary to utilize the advantages of GRP pipes such as excellent hydraulic properties, high corrosion resistance and durability.

diameter (DN) of fiberglass pipes NTT CHEM is measured by the inner diameter in millimeters. The range of pipe dimensions is in mm:

DN 300 - 4000 mm

The nominal ring stiffness (SN) of pipes is measured in N/m² and varies in the following range:

SN 2500 - 1 000 000 N/m²

Most pipe failures arise due to incorrect choice of pipe material, inconsistency of pipe strength with the actual loads encountered during the operation. For the correct selection of the right pipe type, it is important to know the pressure level in the system and the ring stiffness. Usually these values do not exceed 10 atmospheres and 5000-10000 N/m². Fiberglass pipes are available in the following pressure types:

PN 1;

PN 10;

PN 16;

PN 20;

PN 25;

PN 32;

PN 40.

NTT CHEM fiberglass pipes have a safety reserve 1.5 times higher than their nominal value.

Catalog menu

Download catalog

Sertificates

Fill out the application form for equipment in «Innovative Pipe Solutions»