- Home

- Продукция

- Treatment facilities

- Rainwater treatment facilities

Rainwater treatment facilities

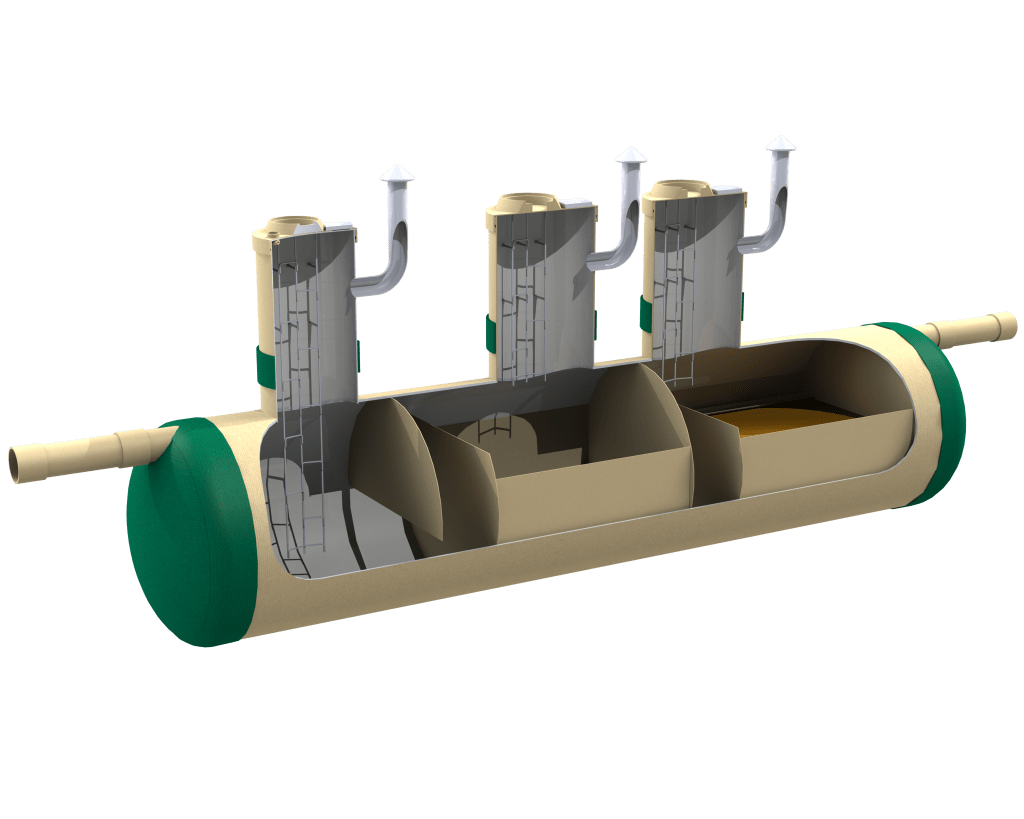

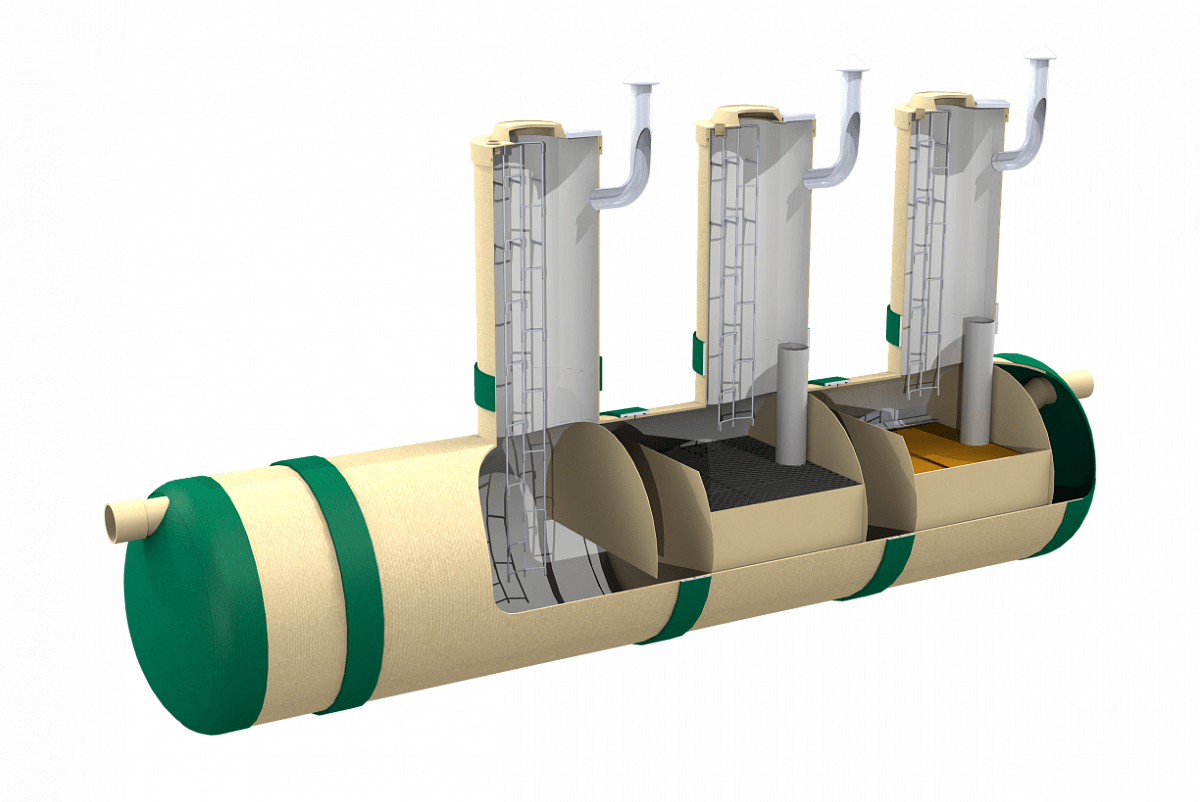

Rainwater treatment facilities are designed to treat surface wastewater to the standards of discharge into water bodies or the municipal rain sewerage.

Helpful information

Helpful information

Designed for treatment of domestic or industrial wastewater of similar composition for further filtration into the ground. The recommended capacity of sewage treatment plant is from 3 to 100 m3/day. After installation treated wastewater should be sent for post-treatment in the filtering trenches, in the fields of underground filtration or biological ponds. Plant location is possible down to a depth of 10 m. Connection is made by means of inlet and outlet branch pipes. Service life is at least 50 years.

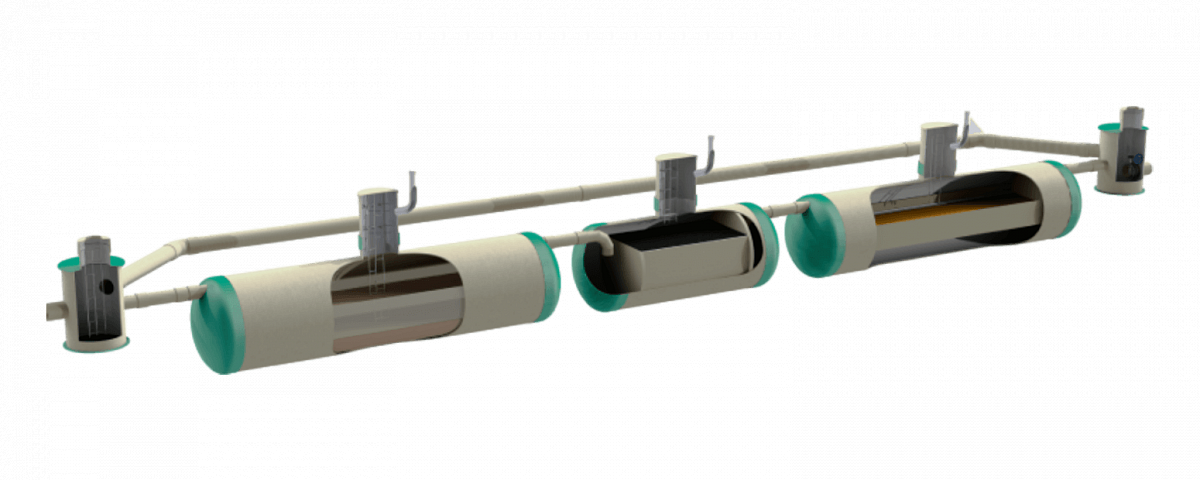

Aerotank

Aerotank

Water through the inlet branch pipe enters the aeration tank, where the main purification of wastewater with the help of microorganisms contained in the activated sludge from organic pollutants and nutrients takes place. In the aeration basin there is also a block of polymeric loading on its surface microorganisms grow in the form of biofilm. Due to the creation of local anoxic conditions in the biofilm the nitrate concentration in wastewater is reduced.

Aeration systemProvides saturation of sludge through aerators from compressor and lets microorganisms breathe, so that biological treatment can be possible.

Secondary settling tank

After the aeration tank, the sludge enters the secondary settling tank to separate the activated sludge. Gravity sedimentation makes it possible to separate wastewater from activated sludge. After that, biologically treated water is sent through the outlet pipe for further disposal in the ground through filtration holes or trenches.

Activated sludge recirculation airlift

Provides continuous biological treatment. Removal of activated sludge from the secondary settling tank into the aeration tank is provided by air supply through a pipeline.

Ventilation riser

Prevents accumulation of gases inside the unit and removes them outside. The cover can be made of fiberglass or aluminum upon request.

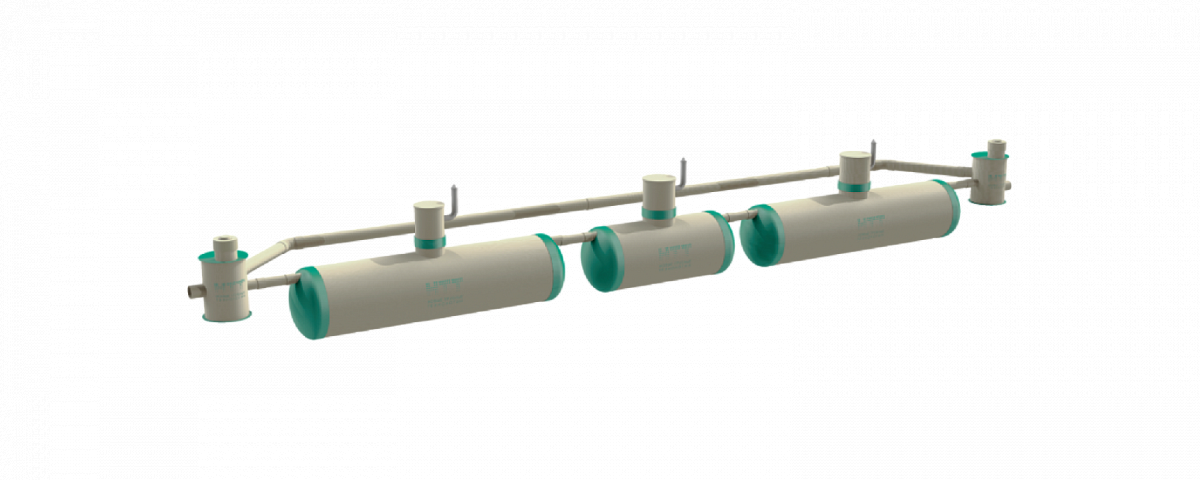

EFFLUENTS > SAND SEPARATOR > OIL AND PETROLEUM SEPARATOR > SORBTION FILTER

Prior the installation of sewage treatment facilities, any excavation pit should be arranged - excavation, water level reduction, sheet piling of the pit walls (if necessary) and a reinforced concrete slab, fixing treatment facilities with synthetic bands (or corrosion-proof steel bands on the rubber seal) to prevent the floating up under the groundwater pressure. Once the sewage treatment plant housing is fixed in its designed position, backfilling is carried out layer by layer, with compaction by vibrating plate, simultaneously on both sides of the sewage treatment facilities housing. After connecting the input and output branch pipes to the rainwater system collector, the service wells are connected, and the second backfilling of the treatment facilities is carried out. After connection to the collector of the rainwater network and backfilling, sewage treatment facilities in one housing are ready for operation. For more details on the installation technology of sewage treatment facilities please refer to the operating manual.

Maintenance of the sewage treatment facilities is performed through the service wells. It is recommended to maintain the one-housing sewage treatment facilities manufactured by NTT-Peresvet at least once a year at the end of the operating season. Maintenance of the treatment facilities should begin with pumping out the oil products accumulated in the oil separator, then pump out the remaining water and sediments in the chambers. Pumping out the treatment facilities should be carried out by organizations licensed to transport and dispose sludge and waste petroleum products. If the sewage treatment facility is equipped with sensors, they should be removed to avoid their damage, then cleaned from contamination and tested their functionality. Coalescence modules of the oil separator are self-cleaning and do not require replacement or rebuilding - cleaning is carried out using non-expandable materials. The sorption filter loading by Megasorb-F sorbent mats is recovered by washing and squeezing. After the recovery, back stacking of sorption mats and installing sensors in place, one-housing treatment facilities must be filled with water up to the level of the output branch pipe.

diameters, housing lengths and heights of service wells must comply with the specific project and must be specified in the product specification. The one-housing sewage treatment facilities belong to the constructions of standard responsibility level of fire resistance and a service life of 50 years.

Q - flow rate: 1-250 l/s

D - housing diameter: 1000-4000 mm

L - housing length: 4000-15200 mm

A - input pipe height: 850-3300 mm

B - output pipe height: 800-3000 mm

N - input/output pipe diameter: 100-700 mm

H - track laying depth: according to customer's design

Q - flow rate: 1-250 l/s

D - housing diameter: 1000-4000 mm

L - housing length: 4000-15200 mm

A - input pipe height: 850-3300 mm

B - output pipe height: 800-3000 mm

N - input/output pipe diameter: 100-700 mm

H - track laying depth: according to customer's design

Video

Catalog menu

Download catalog

Sertificates

Fill out the application form for equipment in «Innovative Pipe Solutions»