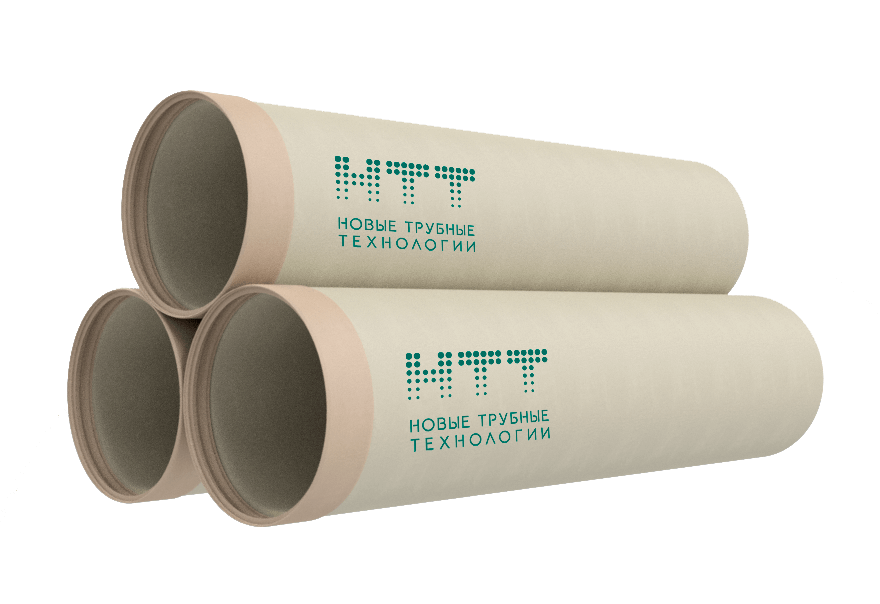

Fiberglass pipes NTT PRO

A perfect alternative to pipes made of traditional materials. Our pipes are a high-tech modern solution for the pipelines construction for drinking and technical water supply, land reclamation and hydropower.

Helpful information

Helpful information

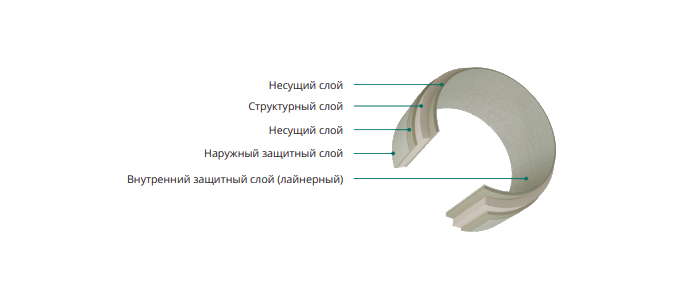

High sanitary and epidemiological properties and approved non-toxicity are the main requirements for pipes that contact with drinking water and food. High eco standards of our products are achieved by using NTT post-polymerization furnace for burning the residual (toxic) styrene and increasing the composite curing, and the smooth inner surface of the pipes minimizes hydraulic friction losses. Besides the obligatory certificates NTT pipes for water supply have received a hygienic quality approvement of the leading Research Institute of the Russian Federation.

Pipes are manufactured using materials of the highest quality. The raw materials used in the pipe production are purchased exclusively from the suppliers who have good reputation with long term cooperation. One of the advantages of NTT PRO pipes is their light weight. There is no need to use special building machinery and additional equipment for installation that saves the cost of construction and installation work.

External laying

a simple and inexpensive method of mounting GRP pipes on concrete or metal supports. This type of installation can also be used for both small and large pipe diameters, the only condition is that a suitably designed pipe support block is available for pressure pipes. The reinforced concrete support block must be designed to withstand the closed gate valve axial loads transmitted through nearby connection and to resist its movement.

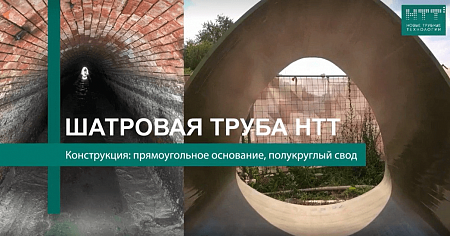

Sanation (Relining)

Sanation of pipelines in cases, tunnels, collectors is an alternative method of laying and is characterized by fast installation of the reconstructed pipeline. For laying fiberglass-reinforced plastic pipes by sanation method they use pipes from 1 to 12 m DN300 up to 4000 mm inclusive, depending on the working procedure, size of starting and receiving pits, diameters of bore holes, deterioration of existing pipes, etc.

There are several methods of sanation:

Pushing

This method is recommended for long sections with pipes less than DN1400 mm to be sanitized. Pipes are lowered into a working pit or concrete chamber (before entering the collector or case) equipped with a jacking station and then pushed forward. The GRP pipeline moves on support rings in case of spacers option or on other support and centering elements.

In the case of short sections and light pipelines with a diameter of less than 1400 mm, the GRP pipes are pulled into the pipe case or collector to be rehabilitated not individually, but by plaits. The pulling is carried out with the help of a winch on sliding supports.

Cart transport

This method is used for the rehabilitation of large diameter pipes over DN 1400 mm and/or of long distance. Both motorized and manual carts are used for transporting pipes. They can be rented or purchased from the NTT Company or manufactured locally.

Underground laying

The most widespread type of laying of pipelines made of fiberglass plastic. Due to light weight and coupling connection, NTT products can be easily and quickly installed in a trench without expensive special machinery according to SP 40-104-2001 and SP 129.13330.2019.

Proper maintenance should be done to prevent significant performance deterioration and functional quality of the pipeline. Proper maintenance is necessary to realize the advantages of fiberglass pipeline over other materials, such as excellent hydraulic properties, high corrosion resistance and durability.

The diameter (DN) of NTT PRO GRP pipes is determined by the internal value and measured in millimeters. The range of pipe sizes in mm:

DN 300 - 3000 mm

DN 300 - 3000 mm

The nominal ring stiffness (SN) of the pipes is measured in N/m² and varies in the following values:

SN 2500 - 1,000,000 N/m².

To choose the right type of pipe is important to know the pressure level of the system. Usually this value is between 10 and 16 atmospheres in water supply systems. For industrial water supply systems the water pressure is higher and can reach a value of PN 40. Fiberglass pipes are available in the following pressure types (PN):

PN 1;

PN 6;

PN 10;

PN 16;

PN 20;

PN 25;

PN 32;

The first three types are the most used. In case of hydraulic shock GRP pipes have a safety margin of 1.5 times more their nominal value.

Video

Catalog menu

Download catalog

Sertificates

Fill out the application form for equipment in «Innovative Pipe Solutions»