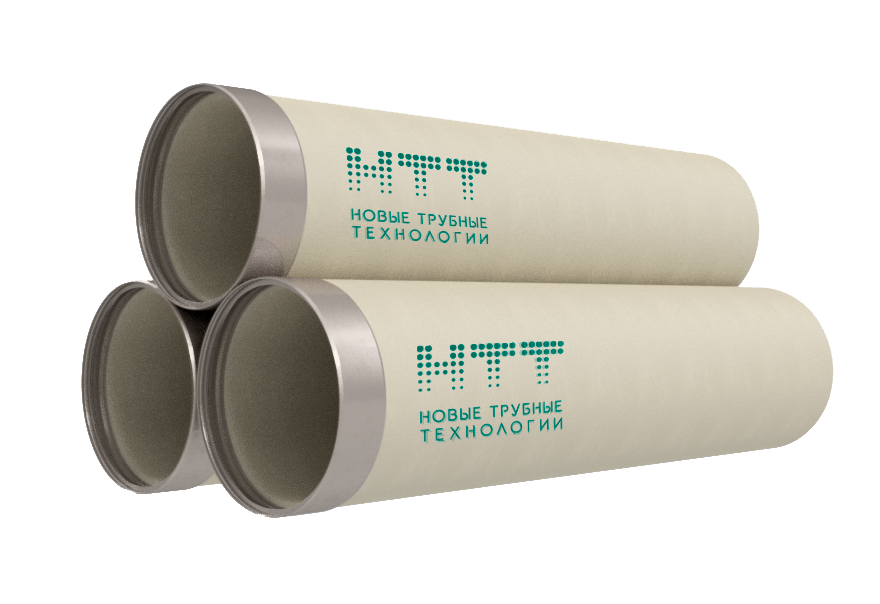

Fiberglass pipes NTT JACKING

Innovative design of NTT specialists for trenchless laying of pipelines. The first GRP jacking pipes of local production for microtunnelling, auger drilling, puncturing and other methods of pressing.

Helpful information

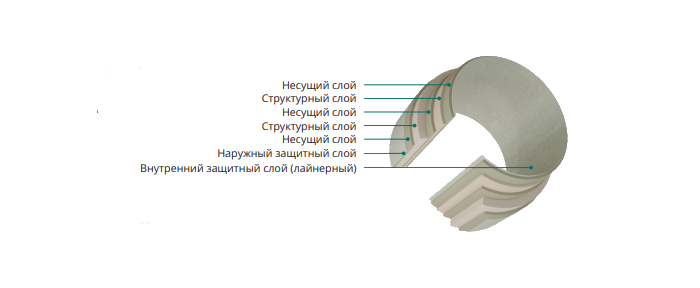

Helpful informationDue to their unsurpassed properties: high resistance to axial loads, high hydraulic characteristics, resistance to corrosion and abrasive wear, high mechanical strength and tightness of joints, NTT JACKING pipes are indispensable for laying by trenchless method.

Trenchless technologies (microtunnelling, auger drilling, puncturing) allow the laying of municipal underground pipelines and pipeline systems of different diameters with no destruction of city buildings, roads, cable networks, etc. along the laying route. Microtunnelling is the most effective when laid at distances up to 1,5 km and at depths up to 80 meters in urban infrastructure. The trenchless technologies offer prompt and effective solutions for replacement, repair and laying the underground lines without causing traffic congestion. The NTT JACKING pipe is a unique pipe with high squeeze/compression strength, while retaining its excellent properties over a long period of time. Due to its smooth outer surface, low weight and small tolerance of outer diameter, the NTT JACKING pipe for microtunneling requires the least jacking force in this technology.

Pipe production with a unique structure and thin wall offers a number of advantages. Jacking pipe installation is performed by the equipment with smaller parameters and tonnage, large-sized construction machinery is not required, which leads to reduction of costs for machinery purchase and rent. Costs for construction site equipment and jacking station are also significantly reduced, and most important, installation costs are reduced due to pipeline laying by microtunnelling method with one operating pipe.

NTT JACKING pipe with recessed steel couplings is designed for laying by microtunnelling method, auger drilling, puncturing (trenchless method of pipeline laying, when the pipe is pressed through the ground for long distances). The method of puncturing is used in conditions of dense city development and heavy traffic. NTT JACKING pipe with recessed steel couplings for relining is designed for renovation the existing pipelines, allowing to minimally reduce the diameter of the renovated pipeline.

NTT JACKING pipes are modern, high quality and available products, which are in many ways better than their analogues. The application area is very wide and is constantly expanding.

unlike steel, cast-iron and polyethylene pipes, GRP jacking pipes can be easily and conveniently installed. For the installation of jacking pipes it is required to use a boring shield of the corresponding diameter and a jacking station. When using GRP jacking pipes, their connection is made thanks to an imported high quality steel coupling, which is already mounted on the pipe.

Maintenance should be carried out to prevent significant deterioration of the performance and functional quality of the pipeline. Proper maintenance is necessary to utilize the advantages of fiberglass pipeline, such as excellent hydraulic properties, high corrosion resistance and durability.

Jacking pipes for laying by the microtunnelling method.

The idea of the method is that pipes are laid in the ground by means of a microtunnelling shield. Its translational movements are ensured by a powerful jacking station, which transmits the pushing force to the shield through a column of fiberglass pipes, which grows as it moves forward. This method involves the excavation of several pits (a starting pit, a receiving pit and in some cases an intermediate pit). Thanks to the cutting tool of the tunneling shield, its gradual advancement ends in the receiving pit, and after its dismantling, you will have a completed collector.

Jacking pipes for laying by auger drilling method.

The method consists of horizontal auger drilling from the starting pit to the receiving pit in a strictly horizontal direction. A special auger drilling tool is equipped with a powerful hydraulic jacking unit, cutting shields and a modern location system. The auger drilling equipment is used to drill using metal pipes, then the column of metal pipes is replaced by GRP jacking pipes by pressing them out. The deviation from the set trajectory varies from 0 to 30 millimeters. The auger drilling method is suitable for work carried out with obstacles of natural and technological origin, such as railroad tracks, highways and roads, houses and rivers.

The auger-drilling technology makes it possible to drill boreholes for laying the jacking pipes up to 100 meters long, depending on the type of the soil.

Jacking pipes for laying by the puncturing method.

Puncture is a trenchless pipe-laying method that is often used to install pipelines in clay and loam soils. This trenchless laying method does not excavate the soil, but compacts it around the pipe in a radial direction. A very significant force is required to puncture, which is achieved with winches, tractors and bulldozers, and most commonly with hydraulic jacks.

Pipes for relining of the existing pipelines.

There are two types of pipeline relining: with breaking the old pipe and without breaking it. Breaking is used in cases where it is necessary to maintain the existing diameter or increase it. Non-breaking relining is used where a small reduction in the inside diameter of the pipe is permitted. In this case there is also no reduction in the flow capacity of the pipe due to the insignificant hydraulic resistance of the GRP pipe.

diameter (DN) of fiberglass pipes "NTT JACKING" is measured by inner size in millimeters. The range of pipe dimensions in mm:

DN 300 - 2500 mm

The nominal ring stiffness (SN) of pipes is measured in N/m² and varies in the following range:

SN 32,000 - 1,000,000 N/m²

Most pipe problems arise from improper choice of pipe material, discrepancy between their strength and the actual loads encountered during installation. For proper selection of the right type of jacking pipe it is important to know the ring stiffness.

NTT JACKING fiberglass pipes have a safety reserve 1.5 times higher than their nominal value.

Video

Catalog menu

Download catalog

Sertificates

Fill out the application form for equipment in «Innovative Pipe Solutions»