- Home

- Продукция

- Pumping stations

- Sewage Pumping Stations

Sewage Pumping Stations

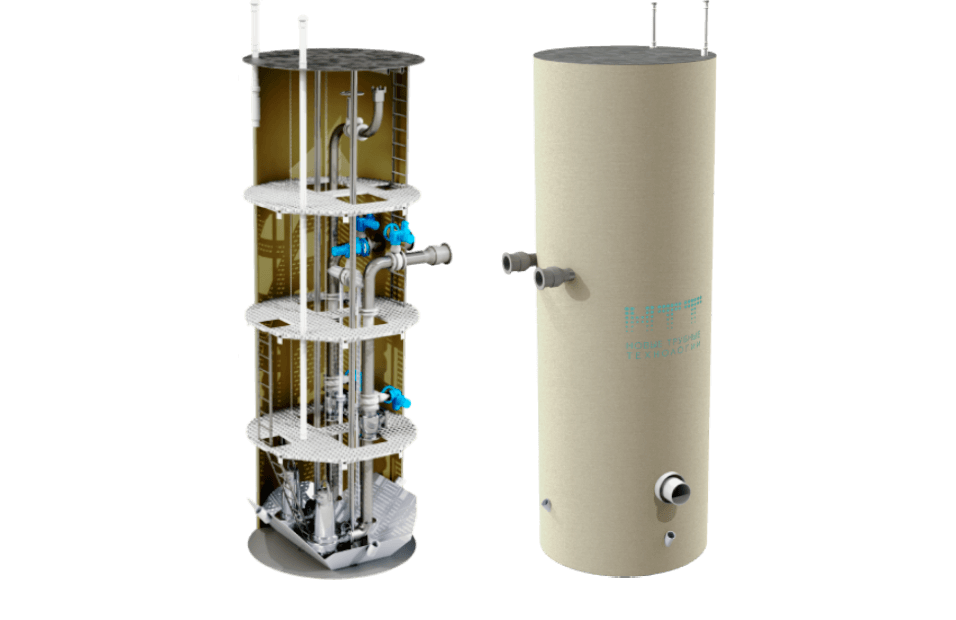

NTT produces sewage pumping stations using fiberglass pipes manufactured by the NTT continuous winding method. Sewage pumping stations are designed for lifting and pumping household, fecal, rain and industrial wastewater where it is impossible to deepen the gravity-flow collectors.

Helpful information

Helpful informationDesigned for pumping wastewater at industrial facilities, municipal and public utilities. NTT company is engaged in design, manufacturing, installation and commissioning of complex automated systems of natural water and wastewater treatment to ensure quality treatment according to the normative criteria.

Is a housing made of fiberglass by the method of continuous winding, with a system of pipelines, valves, service elements (manhole, ladder, elevated service platform, etc.) and immersed or "dry" pump units. To exclude any possible failure in emergency situation, pumps are equipped with temperature sensors of electric motor winding, sensors of bearing temperature, leakage control of end seal. Automated control is performed from the control cabinet with IP54-66 protection in a nearby facility or in a dry inspection manhole with IP54 protection.

Prior the complete sewage pumping station installation in the designed position, the excavation pit should be arranged - excavation, water level reduction, sheet piling of the excavation walls (if necessary) and concrete slab to which the pump housing is fixed with anchors to prevent the floating up under the groundwater pressure. After fixing the pumping station housing in the designed position, the backfilling of the excavation pit around the pumping station is performed layer-by-layer with compaction by vibrating plate. As the backfilling reaches the level of the sewage pumping station branch pipes, the input and output pipes of the sewage pumping station are connected with sewage system collectors and the sewage pumping station housing with the connected collectors is refilled. Then the pump equipment is installed, internal pipelines are installed, float switches are set, and the pump equipment is connected to the control box. The final stage is commissioning and testing.

To ensure trouble-free operation of the electromechanical equipment of the pumping station, it is necessary to observe systematically the readings of the equipment, check the condition of electrical connections, equipment fixing, proper operation of the earthing system of all equipment, and perform periodic maintenance of the pumping equipment. Care and maintenance of pumping units must be carried out in accordance with the pumping unit manufacturer's instructions. When commissioning pumping units after repairs, if the pump cable has been disconnected from the control box, the direction of the motor rotation of must be checked.

Q - flow rate: 1-50 l/sec.

D - housing diameter: 1200-2400 mm

L - housing length (height): 900-8900 mm

A - input pipe height: 700-2200 mm

B - output pipe height: 620-2000 mm

N - input/output pipe diameter: 125-400 mm

H - track laying depth: according to customer's design

Catalog menu

Download catalog

Sertificates

Fill out the application form for equipment in «Innovative Pipe Solutions»